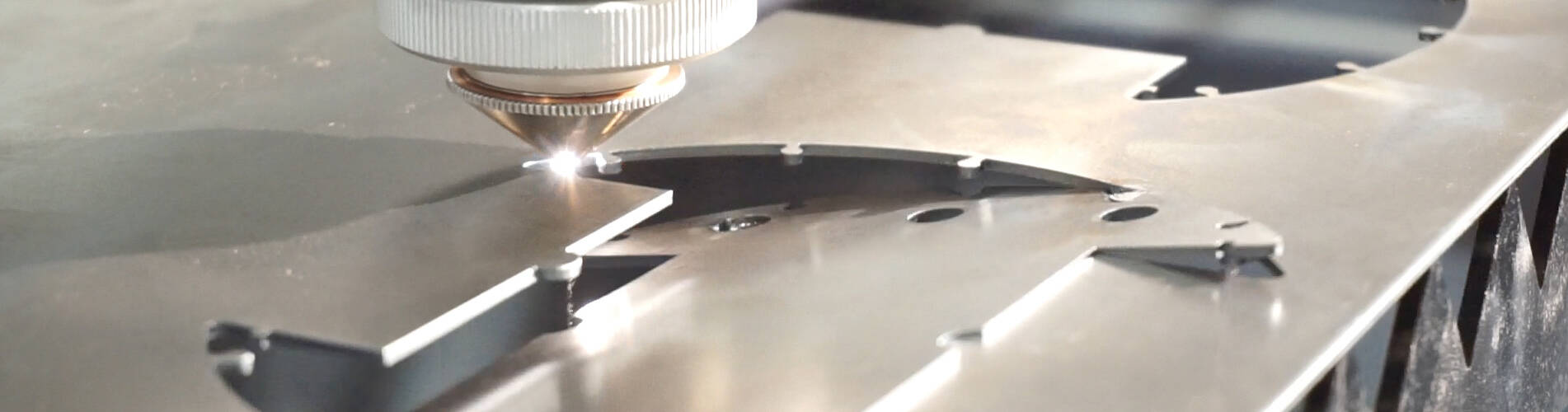

Our company specializes in industrial and commercial laser cutting and other custom fabrication services.

Lead Time:

10daysProduct Orgin:

ChinaShipping Port:

ShenzhenColor:

OEMMOQ:

1Weight:

200g

Provide Custom Laser Cutting Service with Various Metal Material

Product Name: Custom laser cutting steel boards 304 stainless steel plate cut to size

Product Details

Material: stainless steel 304

Thickness: 2mm

Surface finish: clear anodizing

Manufacturing Service: Laser cutting / laser drilling

Drawing File Needed: 2D: DWG,DXF, 3D: ASM,DRW,DWG,DXF,IGS,STEP,etc.

Variations and Similar Processes

Variations on laser cutting include laser drilling, waterjet cutting, laser engraving, fusion cutting, thermal stress cracking and laser welding.

Laser drilling is a process service providers use when they want to create holes, whether for decoration or function. They do so using laser beams, which create holes with tight exact tolerances.

Waterjet cutting subs out lasers from highly pressurized water. By using waterjet cutting, manufacturers can save money, resources and energy. However, waterjet cutting is not universally applicable. Rather, manufacturers can only use it on certain materials. It will not work on hard materials and it will likely break materials like glass.

Laser engraving, or laser etching, lets manufacturers precisely etch surfaces. Instead of melting surfaces, laser engraving vaporizes or fractures surfaces. Manufacturers perform laser engraving with laser engraver machines, which are controlled by a combination of CNC technology, CAD programming, and human operators.

Fusion cutting, also known as melt and blow cutting, involves blowing molten material from the cutting area using pressurized gas. In doing so, manufacturers circumvent the task of raising the material temperature. This process is popular for its low power requirements.

Thermal stress cracking is an alternative to cutting that involves causing thermal expansion via localized surface heating. When applied to especially brittle materials, which are sensitive to thermal expansion, thermal expansion will cause cracking. Manufacturers can use their laser beam to guide this cracking in the pattern they want. Thermal stress cracking works best with glass.

Laser welding, also known as laser beam welding, is a technique laser cutters use to join high volumes of thermoplastics or metals. The laser welding machines emit focused high heat beams that create deep, precise and narrow welds. This process is most useful in automotive manufacturing.

Previous :

3mm black anodizing carbon steel cnc laser cutting and bending metal partsnext :

OEM aluminum sheet fabrication service laser cutting metal plateIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories

Copyright © 2026 Shenzhen Jiamei Photoelectric Technology Co.,Ltd.All Rights Reserved. Powered by dyyseo.com

IPv6 network supported